What Are DC-DC Converters?

DC-DC converters are the backbone of modern electronics, ensuring devices receive the precise voltage they need to function optimally. Whether stepping down power for delicate microcontrollers or boosting voltage for high-energy systems, these converters play a critical role in efficiency and performance.

At CustomPowerLabs, we specialise in designing and manufacturing custom DC-DC converters tailored to your project’s exact requirements. Unlike off-the-shelf solutions, our converters are built to match specific voltage, current, and power constraints, ensuring optimal efficiency, reduced power loss, and extended device lifespan.

How Do DC-DC Converters Work?DC-DC converters function by adjusting voltage levels through high-frequency switching circuits, allowing seamless power conversion with minimal energy waste. Depending on the design, they can either step down (buck), step up (boost), or handle both (buck-boost), making them versatile for a wide range of applications.

Why Choose a Custom DC-DC Converter?- Optimised Performance: Our designs eliminate inefficiencies by fine-tuning every parameter to match your exact power needs.

- Compact & Space-Saving: Unlike generic modules, we create PCBs with the exact footprint and form factor required.

- Reliability & Stability: Custom tuning ensures rock-solid operation, even in demanding environments.

- Tailored Features: Need multiple voltage rails? Integrated protection? Soft-start capabilities? We build it to spec.

Different industries require different power solutions. Our custom DC-DC converters power everything from industrial automation and medical devices to IoT networks and electric vehicles.

- Automotive & EVs: High-voltage converters ensuring battery-to-motor efficiency.

- Renewable Energy: Step-up designs maximising energy from solar panels and battery banks.

- Industrial Equipment: Reliable, high-efficiency converters for robotics and automation.

- IoT & Wearables: Ultra-low-power converters for battery-driven smart devices.

With CustomPowerLabs, you don’t settle for “close enough.” You get a power solution engineered specifically for your needs, ensuring maximum efficiency, reliability, and performance.

Design & Engineering: Crafting Your Ideal Power Solution

At CustomPowerLabs, we don’t just sell DC-DC converters—we engineer solutions tailored to your exact specifications. Whether you need a compact, high-efficiency buck converter for a wearable device or a high-power boost stage for industrial automation, we take your requirements and turn them into precision-engineered power solutions.

Designing a custom power supply isn’t just about selecting components and assembling them—it’s about meticulous optimization to ensure efficiency, stability, and long-term reliability. That’s why our design & engineering process is built to deliver flawless performance from day one.

Custom Schematic Design: The Foundation of a Perfect Power Solution

Every great power design starts with the schematic—the blueprint that determines voltage regulation, efficiency, and overall system stability.

- Precision Voltage Regulation – Optimized for stable voltage output under varying loads.

- Multiple Voltage Rails – Whether you need a single 5V output or a complex multi-rail setup, we design for exact voltage needs.

- High-Efficiency Topologies – Synchronous rectification, resonant converters, and other advanced techniques for minimal power loss.

- Component Optimization – Carefully selected MOSFETs, inductors, and controllers to maximize performance and minimize cost.

Before we even prototype, we ensure every element of your circuit is optimized, reducing waste, increasing efficiency, and preventing costly redesigns.

PCB Layout & Component Selection: Optimized for Performance & Manufacturability

A great schematic is only half the battle—how components are arranged on the PCB impacts efficiency, thermal performance, and EMI compliance.

- Space-Constrained Designs – High-density layouts for compact enclosures.

- Thermal Management – Heat dissipation strategies like copper pours, thermal vias, and optimized trace routing.

- Low Noise & EMI Compliance – Layout techniques to minimize electrical noise and meet industry standards.

- Manufacturing Efficiency – Designed with DFM (Design for Manufacturability) principles to ensure cost-effective production.

With CustomPowerLabs, you get a PCB layout optimized for real-world conditions, ensuring reliable power delivery without compromise.

Simulation & Analysis: Verifying Performance Before Prototyping

We use advanced simulation tools to validate circuit behavior before we even build the first prototype.

- Transient Response Analysis – Ensuring stability under load changes.

- Efficiency & Power Loss Calculations – Fine-tuning components to minimize heat generation.

- Thermal Analysis – Predicting hot spots for optimized cooling strategies.

- EMI & Noise Suppression – Identifying and mitigating potential interference problems.

By catching potential issues early in the design phase, we accelerate development time and reduce costly iterations.

Why Choose CustomPowerLabs for Your DC-DC Converter Design?

Unlike off-the-shelf solutions that force you to adapt your system to the power supply, we design the power supply to fit your system. That means:

- Precision-Engineered to Your Exact Specifications – Every detail, from voltage levels to component selection, is tailored to your needs.

- High Efficiency & Reliability – Maximized efficiency with long-term stability and durability.

- Seamless Manufacturability – Optimized for cost-effective mass production.

- Faster Development with Fewer Revisions – Thanks to advanced simulations and meticulous engineering, we minimize trial-and-error.

At CustomPowerLabs, we ensure your power solution is designed for success from day one—because in high-performance electronics, power isn’t just a detail—it’s everything.

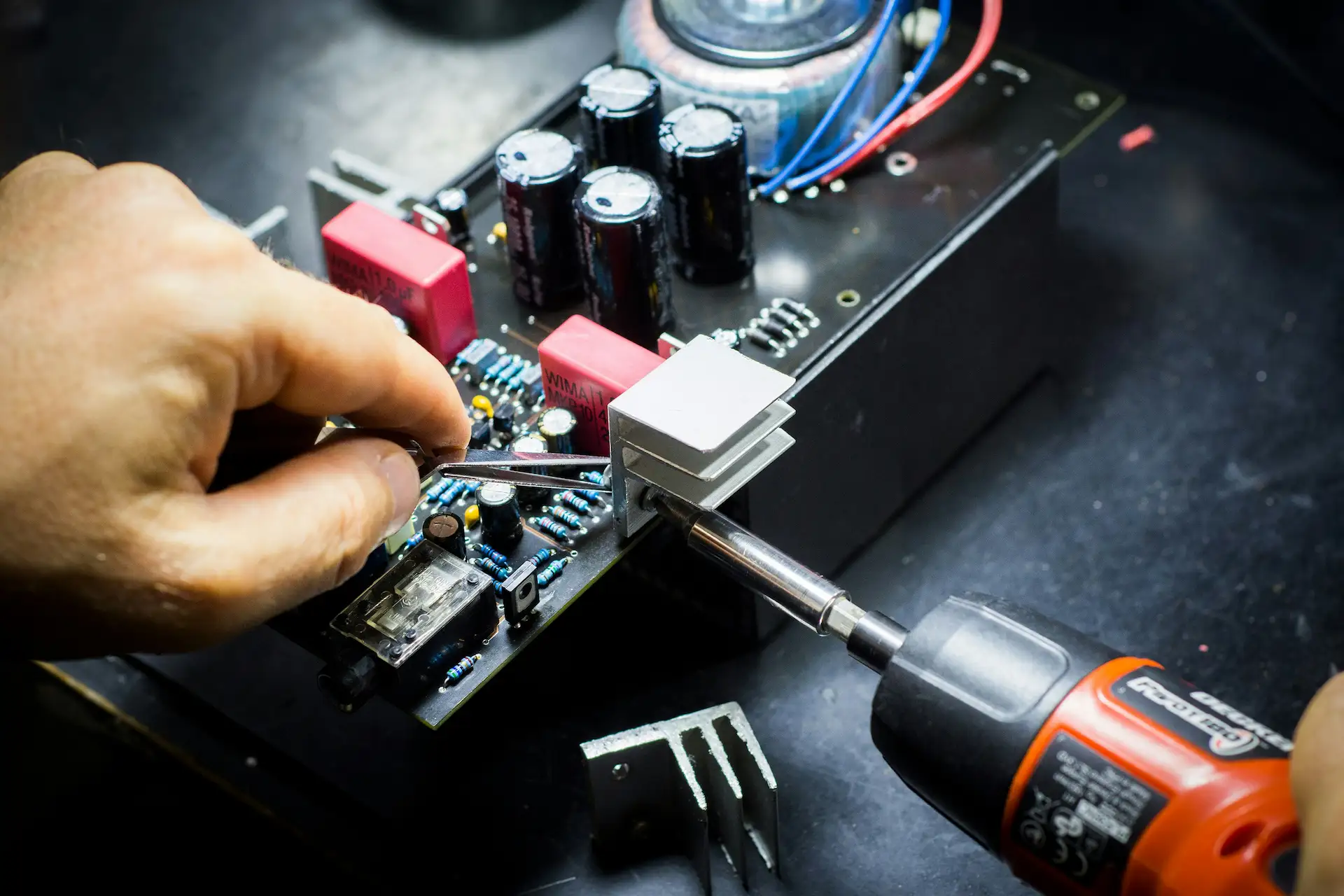

Prototyping: Testing Before Full Production

At CustomPowerLabs, we understand that power electronics need to be tested in the real world before committing to full-scale production. Whether you're developing a new DC-DC converter for a cutting-edge application or refining an existing design, prototyping is the key step that bridges concept and reality.

Many companies, especially those working on mission-critical applications, need to see a working proof of concept before investing in large-scale manufacturing. That’s where our prototyping services come in. We deliver high-quality, small-batch prototypes that allow you to test, refine, and optimize before committing to mass production.

Why Prototyping Matters

Prototyping isn’t just about building a single unit—it’s about verifying performance, identifying potential design issues, and ensuring seamless integration into your system. Without a proper prototype phase, companies risk expensive design flaws, inefficient power delivery, or reliability issues in their final product.

- Proof of Concept Validation – Confirm that your DC-DC converter performs exactly as expected under real-world conditions.

- Cost Savings – Catching inefficiencies or errors early saves time and money before mass production.

- Optimized Performance – Small adjustments to circuit design, component selection, or PCB layout can make a significant difference in efficiency and reliability.

- Investor & Stakeholder Confidence – A working prototype demonstrates your project's feasibility and reliability, helping secure funding or internal approval.

How We Prototype Your Custom DC-DC Converter

1. Rapid Prototyping with High-Quality Components

We don’t cut corners—every prototype we build uses premium components to ensure that the testing phase accurately represents the final product. Our state-of-the-art rapid prototyping process allows us to quickly assemble and refine designs, giving you fast turnaround times without compromising quality.

- Component Selection – We use top-tier MOSFETs, controllers, and inductors to ensure precision performance.

- Flexible Batch Sizes – Need one prototype? Ten? Fifty? We adapt to your development cycle.

- Custom Form Factors – Whether your converter is meant for wearables, automotive, aerospace, or industrial applications, we match your size and integration needs.

2. Lab Testing for Performance & Reliability

A prototype is only useful if it’s thoroughly tested. We put every custom-built DC-DC converter through rigorous in-lab testing, evaluating:

- Efficiency Ratings – Measuring power conversion efficiency to ensure minimal losses.

- Thermal Performance – Identifying hot spots, optimizing heat dissipation, and ensuring long-term reliability.

- Load Testing – Simulating real-world electrical loads to verify stability under varying conditions.

- Electromagnetic Interference (EMI) Testing – Ensuring compliance with industry standards for low noise emissions.

3. Iterative Improvements: Refining Before Production

Prototyping isn’t a one-and-done process. Based on test results and feedback, we work with you to refine and perfect your design before full-scale production.

- Performance Adjustments – Fine-tuning voltage regulation, efficiency, and thermal management.

- Design Modifications – Adjusting PCB layout, enclosure design, or materials for manufacturability.

- Final Validation – Ensuring the converter meets or exceeds performance expectations before scaling up.

Why Choose CustomPowerLabs for Prototyping?

At CustomPowerLabs, we don’t just build power solutions—we build confidence. Our prototyping process ensures that your DC-DC converter is optimized, reliable, and ready for production.

- Fast Turnaround – Rapid prototyping services to keep your project on schedule.

- Expert Engineering Support – Guidance from power electronics specialists to refine your design.

- Comprehensive Testing – Every prototype undergoes in-depth evaluation for efficiency, reliability, and thermal management.

- Scalable to Production – Our prototypes are built with manufacturing in mind, ensuring a seamless transition to mass production when the time comes.

Want to test before you commit? Our team is ready to help you create a high-performance, custom-tailored DC-DC converter prototype that meets your exact needs. Let’s build something powerful together.

Manufacturing: From One-Offs to Mass Production

At CustomPowerLabs, we understand that every project has unique manufacturing needs. Some companies require full-scale production, while others just need a few prototypes before transitioning to in-house manufacturing. That’s why we offer flexible manufacturing options, allowing you to choose the level of involvement that best fits your business model and production goals.

Whether you need a one-off prototype, low-volume production, or a full manufacturing pipeline, we’ve got you covered. Our customized approach ensures you get exactly what you need—nothing more, nothing less.

Flexible Manufacturing Options

We offer three distinct manufacturing pathways to match your project’s specific requirements:

1. Full-Service Manufacturing: We Build It for You

For businesses that want a turnkey solution, we handle everything—from sourcing components to assembling, testing, and shipping finished DC-DC converters. This option is perfect if you need a highly specialized power supply without the hassle of managing manufacturing logistics.

- Prototype to Production – We scale with your needs, from early prototypes to full-volume manufacturing runs.

- Component Sourcing – We procure high-quality parts at competitive prices, ensuring reliability and longevity.

- Automated Assembly – For high-volume orders, we utilize precision pick-and-place assembly lines for consistent, defect-free production.

- End-to-End Testing – Every unit undergoes rigorous testing to meet your exact specifications before it leaves our facility.

- Regulatory Compliance – We ensure your converters meet industry standards (CE, RoHS, UL, ISO, etc.), depending on your target market.

This option is ideal for companies that want high-quality, scalable production without managing supply chains, testing, or logistics themselves.

2. Self-Manufacturing: We Provide the Design, You Build It

If you prefer to handle manufacturing in-house or through a preferred third-party manufacturer, we offer a complete design package, including everything you need to start production.

- Custom Schematic Files – Get fully documented circuit schematics with optimized layouts.

- Gerber Files & PCB Layouts – Ready-to-use files for quick PCB fabrication.

- Bill of Materials (BOM) – A detailed parts list with sourcing recommendations.

- Manufacturing Guides – Step-by-step instructions on assembly, quality control, and testing.

- Firmware (If Required) – Pre-programmed microcontroller code for intelligent power management.

This option is best for OEMs, startups, and companies with existing production capabilities that want to retain control over manufacturing costs and supply chains.

3. Hybrid Approach: We Handle Critical Assembly, You Complete the Integration

For companies that want partial manufacturing support, we offer a hybrid model where we build and test key components while you finalize the integration into your product.

- Partial Assembly – We manufacture and test the core DC-DC power modules, ensuring they meet performance specs.

- Custom Enclosures & Heatsinks – We design and fabricate thermal management solutions.

- Firmware Pre-Programming – If your power system includes an intelligent controller, we’ll program and validate it before shipping.

- Final Integration & Testing – You handle product enclosure assembly, wiring, and system-level testing.

This model gives you maximum flexibility while minimizing risk, making it a great choice for companies that want customized assembly but still control aspects of production.

Key Benefits of Our Manufacturing Options

No matter which manufacturing pathway you choose, you’ll get precision-engineered power solutions tailored to your exact needs.

Scalability: From One Unit to 10,000+

- Whether you need a single prototype, a small production run, or mass manufacturing, we scale seamlessly.

- Our facilities support low-volume specialized production and high-volume automated assembly.

- No unnecessary production—only manufacture what’s needed, reducing waste and costs.

Certified Quality & Reliability

- Every unit undergoes strict testing and validation, ensuring it performs flawlessly under real-world conditions.

- We meet stringent industry standards for safety, efficiency, and longevity.

- Using only high-quality components, we build power supplies that last.

Cost Efficiency Without Compromise

- We optimize component sourcing and manufacturing efficiency, keeping production costs competitive.

- Our flexible models let you decide how much you want to outsource, minimizing overhead costs.

- Whether we manufacture or you do, we design for efficiency, ease of assembly, and long-term reliability.

Which Option Is Right for You?

Choosing the best manufacturing approach depends on your business goals, production capabilities, and budget. Whether you need a few custom power modules or a full-scale production partner, CustomPowerLabs delivers the flexibility and expertise you need to bring your DC-DC power supply to market—efficiently and cost-effectively.

Ready to move forward? Let’s talk about the best approach for your project.

Why Choose Us?

At CustomPowerLabs, we don’t believe in off-the-shelf solutions. Every project is unique, and we craft power solutions tailored exclusively to your requirements. Whether you need a highly efficient DC-DC converter, a multi-rail power system, or an ultra-compact power supply, we engineer designs that fit seamlessly into your application—no compromises, no limitations.

What Makes Us Different?

- Total Customization – Your project isn’t a one-size-fits-all solution, and neither are our designs. We develop power solutions to your exact specifications, ensuring optimal efficiency, reliability, and integration.

- End-to-End Support – From initial concept to final production, we work alongside you at every stage, providing expert guidance, design validation, and hands-on problem-solving.

- Expertise You Can Trust – Our engineers have extensive experience in DC-DC conversion, power regulation, and high-efficiency system design, making sure your power supply delivers flawless performance under real-world conditions.

- No Locked-In Manufacturing – You own your design. Once development is complete, you can choose to manufacture with us or take your design anywhere—we provide the necessary documentation, files, and guidance to ensure seamless production, whether in-house or through a third party.

At CustomPowerLabs, we don’t just design power solutions—we build custom-engineered systems that elevate your technology. Whether you need a one-off prototype, a scalable manufacturing partner, or full ownership of your power supply design, we provide the flexibility, expertise, and quality you need to succeed.

Frequently Asked Questions (FAQs)

What is a DC-DC converter?

A DC-DC converter is an essential electronic device that regulates voltage by stepping it up (boost), stepping it down (buck), or both (buck-boost). These converters ensure that various components in an electrical system receive the precise voltage required for optimal efficiency, performance, and safety.

Why DC-DC conversion is critical:

- Power optimization: Delivers the right voltage to each component without excess loss.

- Improved efficiency: Reduces wasted energy and heat generation.

- System stability: Prevents voltage fluctuations that could damage sensitive electronics.

How do CustomPowerLabs' custom DC-DC converters compare to off-the-shelf solutions?

Unlike mass-produced power modules, our custom-designed DC-DC converters are engineered to match your exact application requirements. This results in improved performance, higher efficiency, and greater reliability compared to generic alternatives.

What sets our solutions apart:

- Tailored voltage regulation: Optimized for your specific power requirements.

- Better efficiency: Reduced energy losses and thermal buildup.

- Compact, application-specific design: Eliminates unnecessary bulk.

- Greater reliability: Built to withstand demanding operating conditions.

Why should I choose a custom DC-DC converter instead of a standard one?

Custom DC-DC converters offer a level of optimization that off-the-shelf solutions simply can't match. By tailoring each converter to your specific needs, you gain significant advantages in performance and integration.

Key benefits of custom solutions:

- Optimized power delivery: Designed for your exact voltage, current, and power needs.

- Compact and efficient: No unnecessary components or wasted energy.

- Enhanced durability: Built for harsh environments and critical applications.

- Custom features: Multi-rail outputs, integrated protection, soft-start, and more.

What industries benefit most from CustomPowerLabs' power solutions?

Many industries rely on precision-engineered power solutions to meet strict performance and efficiency standards. Our custom converters are used across a variety of sectors.

Industries we serve:

- Automotive & EVs: High-voltage converters for battery-to-motor power transfer.

- Renewable Energy: Boost converters for solar panels and battery banks.

- Industrial Equipment: High-efficiency power modules for automation and control systems.

- IoT & Wearables: Ultra-low-power designs for compact, battery-operated devices.

What is involved in the custom design process?

Our design process is structured to deliver high-performance, cost-effective power solutions tailored to your needs. We guide you from initial concept to final production, ensuring efficiency and reliability at every step.

Our custom design workflow:

- Requirement Analysis: Understanding your exact power needs and constraints.

- Custom Schematic Design: Precision-engineered for maximum voltage regulation and efficiency.

- PCB Layout & Optimization: Compact, thermally managed, and EMI-compliant layouts.

- Simulation & Testing: Verifying design performance before prototyping.

Why is prototyping essential before full production?

Prototyping allows us to validate the design before committing to large-scale manufacturing, ensuring the highest levels of performance, reliability, and efficiency.

Key benefits of prototyping:

- Real-world validation: Ensure expected performance under actual operating conditions.

- Early detection of inefficiencies: Catch and resolve issues before mass production.

- Enhanced reliability: Fine-tune power delivery for long-term stability.

- Investor confidence: Demonstrate proof-of-concept before full-scale manufacturing.

How does CustomPowerLabs ensure scalability in production?

We provide flexible manufacturing solutions to accommodate projects of all sizes. Whether you need small-batch production for prototyping or large-scale manufacturing, we offer a tailored approach to ensure seamless scalability.

Our production scalability options:

- Full-Service Manufacturing: We handle everything from sourcing components to final assembly.

- Design Handoff for Self-Manufacturing: Receive complete design files for in-house or third-party production.

- Hybrid Approach: We manufacture key power modules while you manage integration.

What makes CustomPowerLabs different from other power supply providers?

At CustomPowerLabs, we don’t believe in one-size-fits-all solutions. Our focus is on delivering fully customized power solutions that give you complete control over your design.

Why choose us?

- Total Customization: No compromises—solutions tailored to your exact needs.

- End-to-End Support: From concept to production, we guide you through every step.

- Expertise You Can Trust: Decades of experience in power electronics.

- No Locked-In Manufacturing: You own the design, giving you full control over production.

Ready to power up your next project with a custom DC-DC converter? Contact us today for a consultation!