Why Your DC-DC Converter Needs a Custom LCD

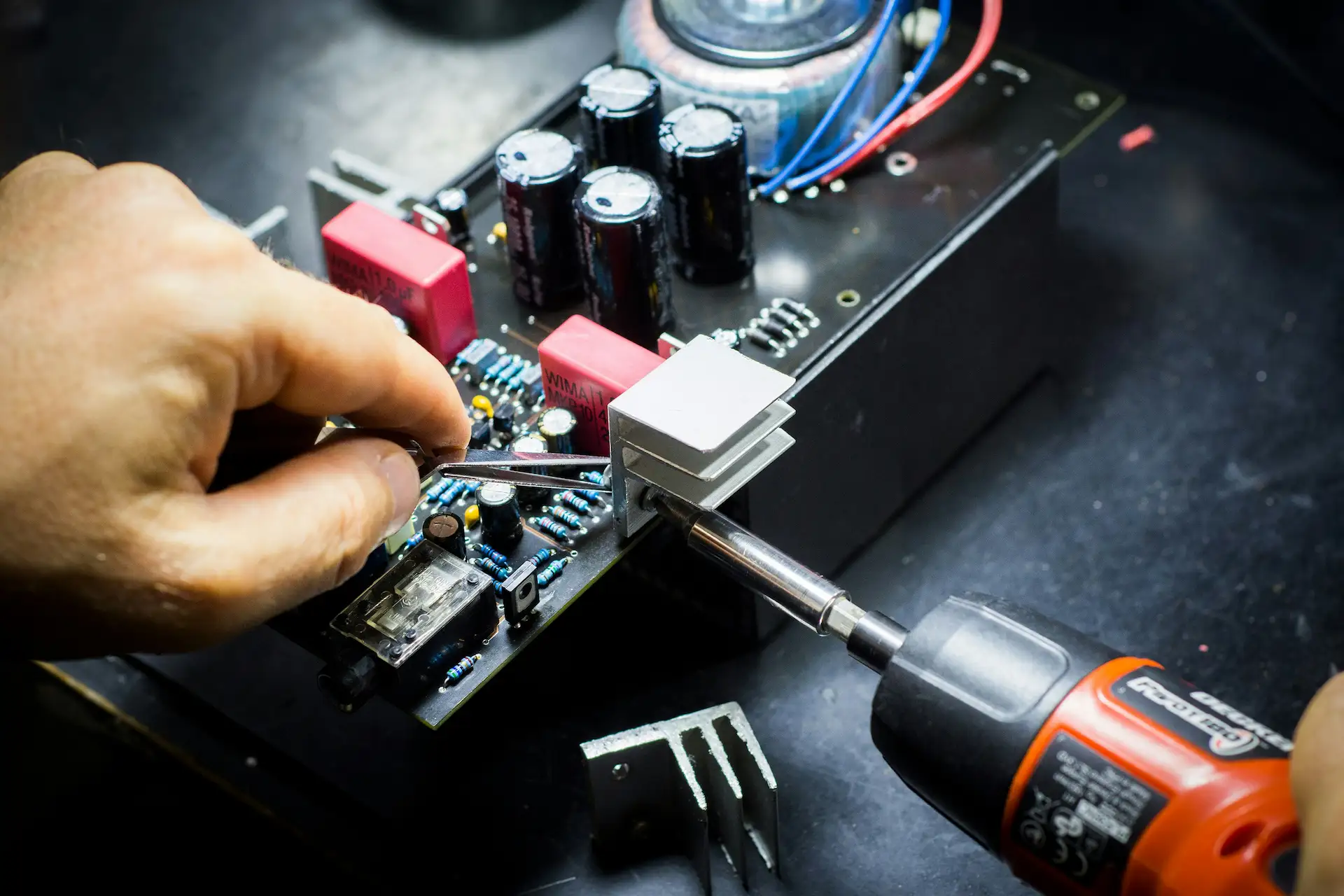

DC-DC converters are the backbone of modern power electronics, efficiently stepping voltage levels up or down to meet the demands of diverse applications. However, real-time performance monitoring is often overlooked, leaving engineers without critical insights into efficiency, voltage stability, and current draw. At CustomPowerLabs, we bridge this gap with high-precision custom LCD displays, transforming your DC-DC converters into intelligent, data-driven systems.

Our custom displays provide immediate access to vital parameters, ensuring that your power supply operates at peak performance. Whether you're stepping down 48V to 3.3V for an IoT sensor, regulating 12V to 5V for a microcontroller, or boosting 12V to 400V for an EV charging system, our LCDs allow you to fine-tune performance, diagnose issues, and optimise efficiency.

Unlike generic off-the-shelf solutions, every display we design is fully customised to your converter's specifications. This includes tailored input and output voltage ranges, efficiency tracking, and physical constraints, ensuring seamless integration into your system. Our advanced microcontroller-driven intelligence and precision sensing deliver millivolt-level voltage accuracy, microamp-level current tracking, and real-time wattage calculations—providing engineers with the granular data they need to achieve maximum reliability and performance.

From R&D labs to production floors, from prototype development to mission-critical applications, our LCD displays empower engineers and designers with real-time insights. Whether you're an innovator refining a next-generation IoT device or an industrial designer optimising a high-power DC-DC converter, our custom LCD solutions ensure you stay in control of your power management system.

Display Options: PCB-Mounted vs. External

The form factor and accessibility of your DC-DC converter dictate the ideal display solution. At CustomPowerLabs, we offer two highly customisable options—PCB-mounted LCDs for seamless integration and external LCD displays for enhanced visibility and control. Each solution is engineered for precision, efficiency, and adaptability to match the unique demands of your power system.

PCB-Mounted LCD Displays: Compact, Integrated Power Monitoring

For compact applications requiring a built-in display, our PCB-mounted LCDs provide real-time monitoring without adding external wiring or enclosures. These displays are directly soldered onto your DC-DC converter’s board, delivering precise voltage, current, and power data in a space-efficient package.

- Sizes: Available in various formats, from 0.66-inch OLEDs (128x64 pixels) for ultra-compact applications to 2-inch TFT displays for enhanced data visualisation.

- Display Types:

- OLED: High-contrast, low-power displays—ideal for battery-powered converters and low-light environments.

- Segment Displays: Simple and rugged, perfect for single-parameter monitoring such as output voltage.

- TFT: Full-colour graphical interfaces for multi-rail monitoring, efficiency curves, and dynamic parameter tracking.

- Customisation:

- Data Fields: Configure the display to show input/output voltage, current draw, wattage, or real-time efficiency metrics.

- Layouts: Choose from numeric grids, bar graphs, or even a startup screen with your custom branding.

- Interfaces: Supports I2C for simple connectivity or SPI for faster data updates.

- Power Consumption: As low as 5mA, drawing minimal power from your converter’s output to maintain system efficiency.

- Mounting Options: Low-profile headers or surface-mount configurations, designed to align perfectly with your PCB footprint.

- Ideal Applications: IoT devices, wearable technology, and any converter where PCB space is a critical factor.

Advantages: No external wiring, fully integrated into your design, and a professional, compact monitoring solution.

Considerations: As it is fixed to the PCB, visibility is dependent on the placement of the board within the system.

External LCD Displays: Big Screens, Big Impact

For DC-DC converters installed in enclosures or requiring remote monitoring, our external LCD displays provide clear, real-time data exactly where you need it. Designed for applications where visibility is critical, these displays ensure you can monitor and adjust your power system with ease.

- Available Sizes: Choose from compact 2.4-inch character displays for simple readouts to large 7-inch touchscreens for full-featured dashboards.

- Display Technologies:

- 7-Segment: High-visibility, robust displays for fundamental voltage and current monitoring.

- Graphic LCD: Monochrome, detailed displays—ideal for presenting multiple parameters in a compact format.

- TFT Touch: Full-colour, interactive displays that allow real-time adjustments, logging, and control.

- Customisation Options:

- Mounting Flexibility: Available with DIN rail clips, panel cutouts, or housed in custom enclosures with IP65-rated protection for harsh environments.

- Connectivity: Supports both wired interfaces (I2C, UART, RS485) and wireless options (Bluetooth, Wi-Fi) for remote data access.

- Data Display: View real-time graphs, historical trends, or multi-converter monitoring on a single screen.

- Power Supply: Can be self-powered via a direct tap from your DC-DC converter or operate from an external 5V-24V power source, depending on system requirements.

- Ideal Applications: Perfect for industrial automation racks, renewable energy systems, and test benches where large-format, easily readable monitoring is essential.

Advantages: Offers flexible placement, enhanced visibility, and upgrade-ready architecture for future expansion.

Considerations: Requires additional wiring or connectors, though our designs minimise complexity while maximising durability.

Core Technology: Microcontrollers & Precision Sensing

Our LCD displays are more than just visual indicators—they are powered by microcontrollers and precision sensing technologies that transform your DC-DC converter into an intelligent power management system. With real-time monitoring, advanced calculations, and seamless integration, our displays ensure that every watt of power is accounted for with maximum accuracy.

Microcontrollers: The Heartbeat of Your Display

Every display we design runs on a microcontroller—an embedded processing unit that continuously gathers data, processes key power parameters, and updates your LCD in real time. These microcontrollers do much more than simply show numbers—they enable dynamic power insights, helping you fine-tune efficiency and troubleshoot issues instantly.

- Core Capabilities:

- Reads voltage and current sensor outputs via 12-bit or 16-bit ADCs, offering resolution as precise as 0.001V.

- Calculates power consumption using the formula P = V × I and efficiency using (Pout / Pin) × 100% in real time.

- Drives the LCD display with high refresh rates—up to 60Hz for fluid, responsive updates.

- Microcontroller Options:

- Low-Power: STM32L0 series, ideal for battery-powered applications with ultra-low sleep currents (<1µA).

- High-Performance: STM32F4 series for advanced multi-rail monitoring, complex calculations, and additional features.

- Custom Firmware:

- Written in C or C++, ensuring efficient and reliable execution.

- Supports advanced features like overcurrent detection, real-time logging to onboard flash storage, and I2C master-slave communication.

- Seamless Integration: Designed to operate efficiently on your PCB or in an external module, with minimal power draw (10mA at 3.3V).

Why It Matters: Your display isn’t just showing numbers—it’s a critical diagnostic tool that gives you full visibility into your converter’s performance, helping you maximise efficiency and stability.

Precision Sensing: Voltage, Current, and Wattage Mastery

Accurate power monitoring depends on high-precision sensing. Our system ensures that every voltage fluctuation, current draw, and power trend is measured with industry-leading accuracy.

Voltage Sensing

We capture every millivolt fluctuation to give you the most detailed picture of your converter’s performance.

- Measurement Method: Utilises high-precision voltage dividers with 0.1% tolerance resistors or advanced INA219 high-side sensing chips.

- Measurement Range: Configurable from 1V to 100V, with custom scaling options available.

- Accuracy: Achieves ±0.5% standard, with optional ±0.1% calibration for lab-grade precision.

- Noise Suppression: Onboard capacitive filtering and software-based averaging eliminate ripple interference.

Current Sensing

Precision current measurement ensures that every milliamp is tracked—whether your system operates in microamps or heavy-duty amp loads.

- Sensing Techniques:

- Shunt Resistors: Ultra-low resistance (1mΩ to 100mΩ), paired with differential amplifiers such as INA226 for high-accuracy readings.

- Hall Effect Sensors: Non-contact current sensing using components like ACS712, perfect for high-current applications up to 50A.

- Measurement Range: Customisable from 10µA to 50A+, tailored to your power system’s requirements.

- Factory Calibration: Pre-calibrated to ensure zero drift and absolute accuracy in real-world conditions.

Wattage & Efficiency Monitoring

Live power consumption data allows you to track efficiency, detect power anomalies, and optimise system performance.

- Real-Time Calculations: Microcontroller calculates instantaneous wattage using P = V × I every millisecond.

- Display Options: Output can be shown as raw wattage (e.g., "15.32 W"), efficiency percentages, or load-based trend analysis.

- Advanced Features:

- Overpower Warnings: Alerts when current draw exceeds safe limits.

- Peak Logging: Stores highest recorded power loads for performance analysis.

- Efficiency Curves: Tracks power output trends across different load conditions.

Why It Matters: Your converter’s efficiency and reliability are only as good as the data you collect—our precision sensing solutions ensure every critical parameter is monitored with millivolt and microamp accuracy.

Applications: Where Your DC-DC Converters Shine

Pairing your custom DC-DC converters with our advanced LCD displays enhances power monitoring, efficiency tracking, and real-time diagnostics across a wide range of industries. Here’s where our tailored solutions make the biggest impact:

- Industrial Automation: Real-time monitoring of 24V-to-5V power conversions driving PLCs and motor controllers. External LCD displays provide at-a-glance insights into wattage consumption and system efficiency, ensuring seamless factory operations.

- IoT & Wearables: Miniature PCB-mounted OLEDs track ultra-low-power voltage conversions, such as 3.7V-to-1.8V step-downs, optimizing battery life in compact IoT sensors, smartwatches, and other wearable devices.

- Renewable Energy: Boost converters in solar power systems require precise voltage regulation—our rugged external LCD screens provide critical real-time data on 12V-to-48V power steps, ensuring peak efficiency and stability in off-grid installations.

- Automotive & EVs: High-voltage DC-DC systems, such as 400V-to-12V step-downs in electric vehicles, demand robust monitoring. Our isolated sensing technology combined with full-color TFT displays enables real-time diagnostics and performance tracking.

- Prototyping & R&D: From breadboard experiments to production-ready circuits, our LCD displays provide real-time feedback on 5V-to-15V step-ups and custom voltage rails, allowing engineers to fine-tune their designs with precision.

Your Competitive Edge: Our high-precision LCD displays don’t just visualize data—they elevate your DC-DC converters by providing clear, accurate, and real-time insights into power usage, efficiency trends, and system health.

FAQs: Your DC-DC Display Questions, Answered

How customisable are these displays?

Our displays are fully bespoke, designed to meet the exact needs of your project. Whether you're looking for a specific screen size, a particular type of display technology, or custom firmware logic, we tailor every aspect to ensure seamless integration.

Customisation options include:

- Size & Form Factor: Choose from standard sizes or request a unique shape for your application.

- Data Display: Configure real-time voltage, current, power, and other essential metrics.

- Interface Selection: Supports multiple communication protocols for smooth integration.

- Firmware Logic: Custom software allows for advanced functionality, from alarms to dynamic adjustments.

What accuracy can I expect?

Precision is crucial when monitoring DC-DC power systems, and our displays are built for high accuracy. Voltage and current readings achieve ±0.5% accuracy, with further calibration options available for even greater precision.

Accuracy highlights:

- Real-time wattage calculations: No delay in power readings, ensuring immediate feedback.

- High-resolution ADCs: Enables precise monitoring of low- and high-power applications.

- Advanced calibration support: Fine-tune measurements for laboratory or industrial precision.

Can your displays handle high-power DC-DC converters?

Yes! Our displays are designed to work with high-power applications, supporting voltages up to 100V and currents exceeding 50A. For even higher loads, we offer custom sensor solutions that scale to meet your specific power requirements.

Key features for high-power applications:

- Robust voltage handling: Supports a wide range of DC power inputs.

- High-current sensing: Handles large loads without compromising accuracy.

- Custom sensor integration: Solutions available for extreme power levels.

Do your displays support multi-output converters?

Absolutely. Our screens can simultaneously monitor multiple output rails, ensuring real-time tracking of different voltage levels such as 3.3V, 5V, 12V, or custom outputs. We use isolated sensing to prevent interference and maintain measurement accuracy.

Why multi-output support matters:

- Optimised power distribution: Monitor and balance multiple voltage rails effectively.

- Isolated measurement techniques: Ensures accurate readings without cross-talk.

- Flexible configuration: Adaptable to a wide variety of DC-DC converter designs.

What communication interfaces do your LCDs support?

We offer a wide range of communication options to fit different system architectures, including both wired and wireless solutions. Whether you need a direct connection to a microcontroller or remote monitoring over the network, our displays are built for seamless integration.

Supported communication protocols:

- Wired: I2C, SPI, UART, RS485 for real-time, high-speed data transfer.

- Wireless: Wi-Fi and Bluetooth for remote monitoring and cloud-based applications.

- Custom protocols: Additional integration options available upon request.

Why choose CustomPowerLabs?

At CustomPowerLabs, we specialise in DC-DC power systems, delivering precision-engineered solutions tailored to your needs. Our expertise in custom power monitoring, high-accuracy sensing, and embedded system design ensures that your display works flawlessly with your DC-DC converter.

What sets us apart:

- Expertise in DC-DC systems: Designed specifically for power electronics applications.

- High-precision sensing: Ensures reliable performance across all conditions.

- Custom engineering support: Work with our team to create a display solution that perfectly fits your project.

Ready to transform your DC-DC converters with real-time power intelligence? Contact us today, and let’s build something exceptional.