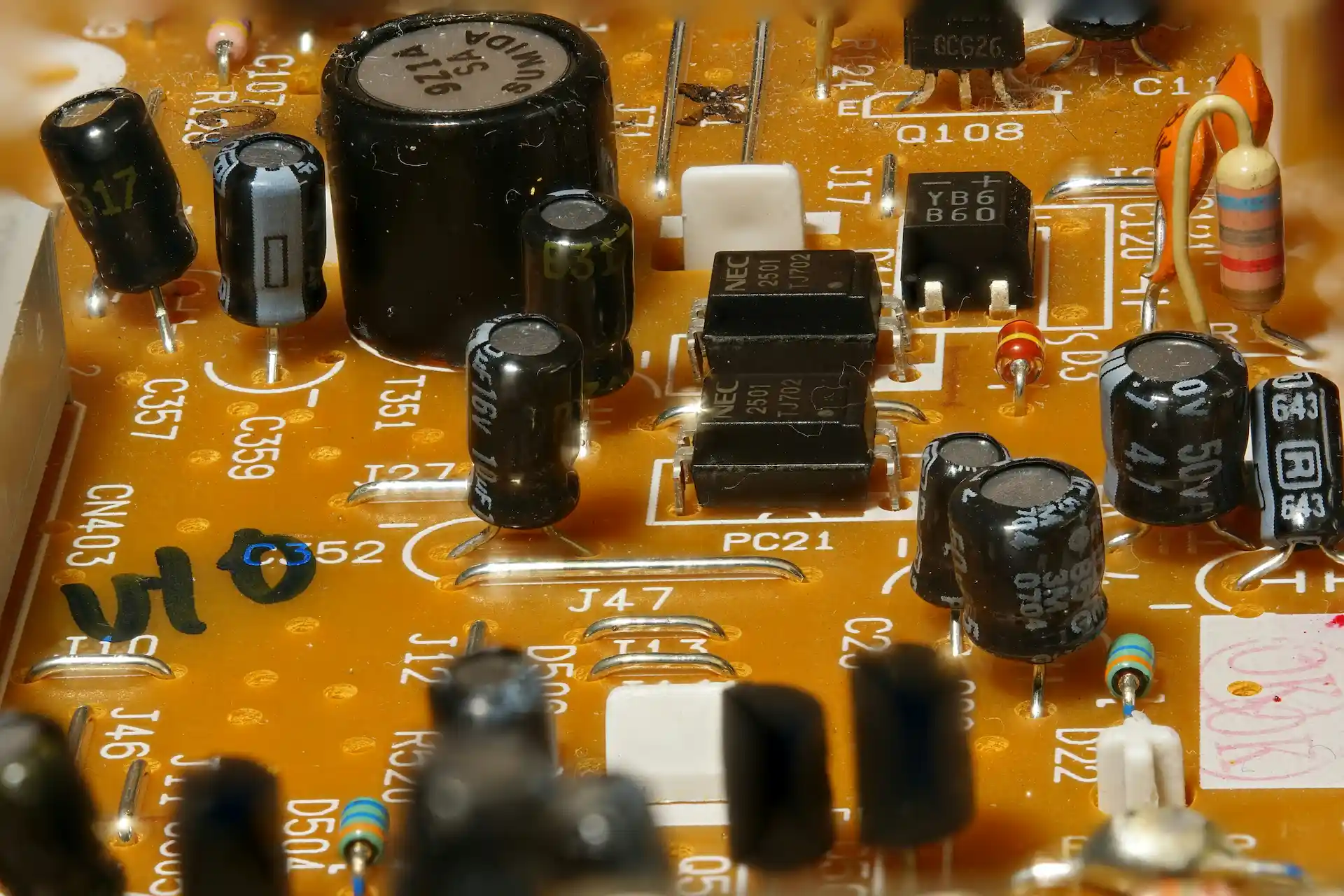

What Are DC-DC Converters?

DC-DC converters are vital components in modern electronics, transforming one DC voltage level into another to deliver precisely what your devices need. They optimize performance and efficiency by stepping down voltage from batteries in portable gadgets or boosting it from low-power sources like solar cells. These unsung heroes ensure stable power delivery across countless applications.

Types of DC-DC Converters

Buck Converters (Step-Down)

A buck converter, also known as a step-down converter, reduces a higher input voltage to a lower output voltage. These converters are widely used in battery-operated devices, microcontrollers, and power-sensitive electronics, where efficient power regulation is essential.

How a Buck Converter Works:

It operates using switching regulation:

- Switching ON: The input voltage is applied across an inductor, storing energy in its magnetic field.

- Switching OFF: The inductor releases stored energy to the output capacitor, supplying power at a lower voltage.

- Control Mechanism: A pulse-width modulation (PWM) controller adjusts the duty cycle to maintain a steady output voltage.

Advantages of Buck Converters:

- Highly Efficient – Typically above 90% efficiency, minimizing energy waste.

- Compact & Lightweight – Ideal for portable electronics like smartphones, tablets, and laptops.

- Battery-Friendly – Ensures stable power to sensitive components, extending battery life.

Common Applications:

- Smartphones & Tablets: Ensures stable 5V power for charging circuits.

- Embedded Systems & Microcontrollers: Converts 12V or 24V down to 3.3V or 5V.

- Electric Vehicles: Powers infotainment and low-voltage systems from a high-voltage battery pack.

Boost Converters (Step-Up)

A boost converter, or step-up converter, does the opposite of a buck converter—it increases a lower input voltage to a higher output voltage. This is critical for low-power sources like solar panels or single-cell batteries that need to power higher-voltage components.

How a Boost Converter Works:

- Switching ON: The inductor stores energy from the input power source.

- Switching OFF: The stored energy is released, combining with the input to create a higher voltage at the output.

- Control Circuitry: The PWM controller adjusts the switching frequency to regulate the output voltage.

Advantages of Boost Converters:

- Efficient Power Utilization – Enables low-voltage sources to power high-voltage devices.

- Compact and Lightweight – Used in solar, automotive, and battery-operated systems.

- Improves Battery Performance – Effectively draws power from low-voltage batteries.

Common Applications:

- Solar Power Systems: Converts low 3-12V DC solar outputs into usable higher voltages.

- Automotive LED Lighting: Steps up 12V car battery power for LED arrays.

- Portable Power Banks: Boosts 3.7V lithium battery power to charge 5V USB devices.

Buck-Boost Converters

A buck-boost converter combines the capabilities of both buck and boost converters, allowing it to step up or step down voltage as required. This makes it ideal for systems where the input voltage fluctuates above and below the desired output voltage.

How a Buck-Boost Converter Works:

- Utilizes a single inductor and switching MOSFET to store and release energy.

- Can operate in either buck mode (step-down) or boost mode (step-up) depending on input voltage conditions.

Advantages of Buck-Boost Converters:

- Handles Wide Input Voltage Ranges – Works even when the power source varies significantly.

- Compact & Efficient – A single circuit provides both voltage increase and reduction.

- Reliable Power Regulation – Ideal for battery-powered and automotive systems.

Common Applications:

- Electric Vehicles: Regulates fluctuating battery power for multiple systems.

- Laptop Power Adapters: Accepts various input voltages and outputs a stable 19V for charging.

- Wearable & Medical Devices: Ensures constant voltage operation despite battery drain.

Isolated DC-DC Converters

An isolated DC-DC converter differs from other types because it electrically separates the input and output circuits. Using a transformer or optocoupler, this type of converter is crucial for high-voltage applications, industrial automation, and medical equipment, where safety and EMI reduction are key concerns.

How an Isolated DC-DC Converter Works:

- Step 1: Input power is converted to AC using a high-frequency switching circuit.

- Step 2: AC power is transferred across a transformer, ensuring electrical isolation.

- Step 3: Output rectification converts AC back into a stable DC voltage for the load.

Advantages of Isolated Converters:

- Enhanced Safety – Protects against ground loops and high-voltage faults.

- Superior Noise Immunity – Reduces electromagnetic interference (EMI).

- Reliable Performance in Harsh Environments – Used in industrial, aerospace, and medical applications.

Common Applications:

- Medical Equipment: Powering MRI, X-ray, and patient monitoring devices.

- Industrial Automation: High-voltage machine control systems requiring isolation.

- Aerospace & Defense: Ensures safety in avionics and satellite communications.

Applications of DC-DC Converters

DC-DC converters play a critical role in modern electronics, ensuring devices receive the correct voltage and operate efficiently. They are widely used across industries where power management, energy efficiency, and system stability are essential. Below are some of the most common and impactful applications:

Consumer Electronics: Powering Smartphones, Laptops, and Portable Devices

In the fast-paced world of consumer electronics, efficient power regulation is key. DC-DC converters are essential in devices like smartphones, tablets, and laptops, ensuring stable power supply while optimizing battery life.

- Battery Power Management: Converts varying battery voltage levels (e.g., lithium-ion batteries that drop in voltage over time) into a stable output to power screens, processors, and sensors.

- Fast Charging Technologies: Many modern chargers use high-efficiency DC-DC conversion to step up/down voltages for fast and safe charging.

- Voltage Regulation for Sensitive Components: Ensures microprocessors and memory modules receive the exact voltage required, preventing damage and improving efficiency.

Electric Vehicles: Managing High-Voltage Battery Power

With the rise of electric mobility, DC-DC converters play a vital role in electric vehicles (EVs), hybrid electric vehicles (HEVs), and plug-in hybrid vehicles (PHEVs). The high-voltage main battery pack needs to supply various subsystems, each requiring different voltage levels.

- Traction Inverters: Convert battery power to drive electric motors at high efficiency.

- Low-Voltage Systems: Steps down high-voltage (400V–800V) battery power to 12V or 24V for onboard systems like lighting, infotainment, and safety electronics.

- Battery-to-Battery Charging: Manages power distribution between multiple battery modules in hybrid vehicle systems.

Renewable Energy Systems: Maximizing Efficiency in Solar and Wind Power

DC-DC converters are crucial in solar and wind energy systems, where power generated must be converted and conditioned before being stored or used.

- Solar Panel Power Conversion: Most photovoltaic (PV) panels generate DC voltage that fluctuates with sunlight intensity. A DC-DC converter helps regulate and step up or down this power for inverters or direct DC loads.

- MPPT (Maximum Power Point Tracking): Many solar controllers use DC-DC conversion to continuously adjust voltage and maximize energy harvest from the panels.

- Grid Integration: Converts renewable energy output into appropriate voltage levels for storage batteries or AC conversion.

IoT (Internet of Things) and Low-Power Devices

IoT devices rely heavily on low-power operation, often running on batteries or energy harvesting systems that provide inconsistent voltage levels. DC-DC converters optimize these power sources to ensure reliable operation.

- Wearable Technology: Converts small battery power into stable voltages for smartwatches, fitness trackers, and medical wearables.

- Remote Sensors: Many industrial and environmental sensors operate in remote locations using solar panels or kinetic energy harvesting, requiring highly efficient DC-DC converters.

- Smart Home Devices: Converts standard battery power to usable voltages for connected home automation systems like thermostats, smart locks, and security cameras.

Aerospace and Defense: Mission-Critical Power Conversion

In aerospace, satellites, and defense applications, power reliability is non-negotiable. DC-DC converters are designed to withstand extreme conditions, providing stable and isolated power in environments with high radiation, vibration, and temperature variations.

- Satellite Power Systems: Spacecraft require DC-DC converters to manage power from solar arrays and batteries, distributing regulated voltages to different onboard instruments.

- Military Communication Equipment: Ensures secure and stable power conversion in field radios, radar systems, and avionics.

- Autonomous Drones and UAVs: Converts battery power for flight controllers, sensors, and communication systems.

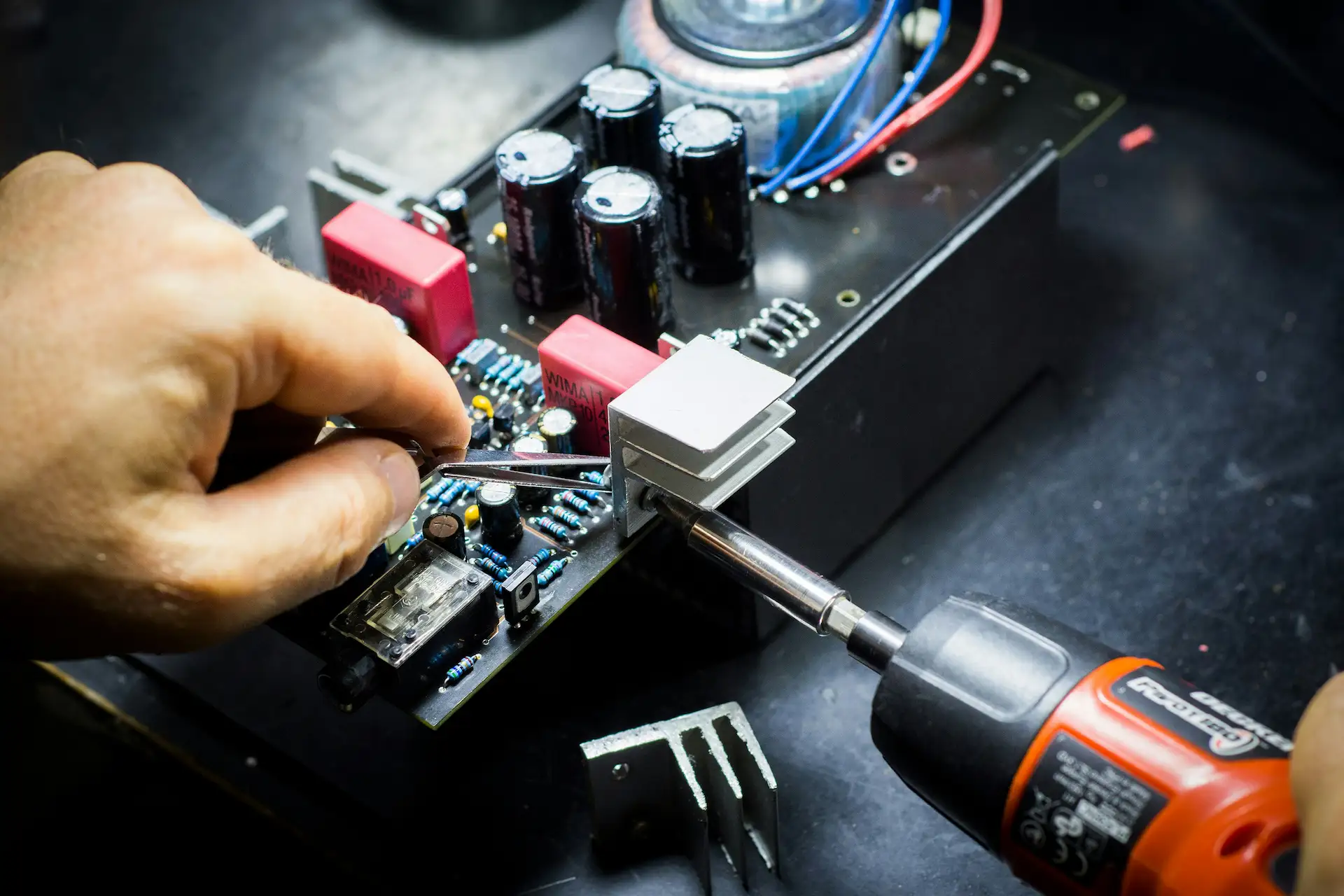

Industrial Automation and Robotics

DC-DC converters are critical in factory automation, robotics, and motor-driven applications where precise voltage control is needed for efficiency and safety.

- Robotic Arms: Many industrial robots require different voltage levels for motors, sensors, and computing units.

- Motor Controllers: Many motor-driven systems use DC-DC converters to regulate power to electric drives.

- Factory Power Distribution: Converts high-voltage DC bus power to lower, application-specific voltages.

Medical Equipment: Reliable Power for Life-Saving Technology

DC-DC converters play an essential role in the medical field, where equipment must meet stringent power stability and safety standards.

- Patient Monitoring Devices: Converts battery or wall power to regulated levels for ECGs, pulse oximeters, and vital sign monitors.

- Imaging Systems: High-voltage DC-DC converters power CT scanners, MRI machines, and X-ray imaging devices.

- Implantable Medical Devices: Low-power DC-DC converters regulate voltage in pacemakers, hearing aids, and neurostimulators.

Telecommunications and Data Centers

With the demand for faster and more efficient data transmission, telecom networks and data centers rely on DC-DC converters for optimized power management.

- Base Stations and 5G Infrastructure: Converts high-voltage DC power to lower levels for networking equipment.

- Server Racks: Regulates power to CPUs, memory banks, and storage systems.

- UPS (Uninterruptible Power Supplies): Ensures stable voltage output in the event of power fluctuations.

DC-DC converters are a cornerstone of modern electrical engineering, ensuring that devices, from small IoT sensors to large industrial machines, receive the correct and most efficient power supply possible. If you're looking for custom-built DC-DC converter solutions tailored to your application, contact us today to discuss your needs.

Benefits of Custom DC-DC Converter Designs

Off-the-shelf converters work, but custom designs take it to the next level:

- Optimized Efficiency: Tailored to your exact voltage and current needs, minimizing power loss.

- Compact Size: Built to fit tight spaces, perfect for sleek, portable devices.

- Cost Savings: Integrated features reduce overall system costs by eliminating extras.

- Enhanced Reliability: Designed to endure your specific environmental and operational challenges.

At CustomPowerLabs, we craft bespoke DC-DC converter solutions that align perfectly with your project, delivering top-tier performance and efficiency.

FAQs About DC-DC Converters

What is the efficiency of a typical DC-DC converter?

Modern designs often exceed 90% efficiency, depending on the application and configuration.

Can DC-DC converters handle high currents?

Absolutely—specialized converters are built for high-current applications, such as electric vehicles, industrial power supplies, and telecommunications infrastructure. These converters use advanced switching techniques, thermal management, and high-efficiency components to safely deliver large amounts of power.

How do I choose the right DC-DC converter?

Consider the following key factors:

- Input Voltage Range: Ensure it matches your power source (e.g., batteries, solar panels, or industrial power supplies).

- Output Voltage & Current: Choose a converter that meets your device’s power requirements.

- Efficiency: High-efficiency converters minimize power loss and heat generation.

- Size & Form Factor: Compact designs are ideal for space-constrained applications.

- Isolation Needs: For safety-critical applications, consider isolated DC-DC converters.

- Environmental Factors: Ensure it can handle temperature extremes, vibrations, or moisture if used in rugged environments.

What happens if my DC-DC converter overheats?

Overheating can be caused by excessive load, inadequate ventilation, or inefficient design. Solutions include:

- Ensuring proper heat dissipation using heat sinks, cooling fans, or thermal pads.

- Using a converter with built-in thermal shutdown and current limiting features.

- Optimizing PCB design to minimize power losses and hot spots.

Are DC-DC converters suitable for sensitive electronics?

Yes, but selecting the right converter is critical. Look for:

- Converters with low ripple and noise to prevent interference with sensitive circuits.

- Soft-start features that prevent inrush currents that could damage components.

- Post-regulation techniques to stabilize the output voltage if ultra-low noise is required.

What’s the difference between isolated and non-isolated DC-DC converters?

- Isolated DC-DC Converters: Provide galvanic isolation between input and output using transformers or optocouplers, essential for medical, industrial, and aerospace applications.

- Non-Isolated DC-DC Converters: More compact and efficient but do not provide isolation, making them suitable for consumer electronics and automotive applications.

How do DC-DC converters affect battery life?

Efficient converters extend battery life by reducing power losses. Factors that help improve battery performance include:

- Choosing high-efficiency converters that minimize energy wastage.

- Using converters with low quiescent current to reduce idle power consumption.

- Optimizing voltage regulation to prevent excessive battery drain in portable devices.

Can a DC-DC converter stabilize fluctuating input voltage?

Yes, certain converters are designed for this purpose:

- Buck-boost converters handle both step-up and step-down conversion, making them ideal for systems with fluctuating input power.

- Supercapacitor-backed converters help smooth out momentary voltage drops in automotive and industrial settings.

What are common failure signs of a DC-DC converter?

Common indicators include:

- Unstable output voltage: Often due to aging capacitors, excessive ripple, or MOSFET failures.

- Excessive heat generation: Could indicate overloading, poor design, or inadequate cooling.

- Audible noise (whining or buzzing): May be caused by switching frequency issues, loose inductors, or bad filtering.

- Intermittent shutdowns: Suggests thermal shutdown, current overload, or faulty input connections.

Can multiple DC-DC converters be used in parallel?

Yes, but proper load balancing is required. Common methods include:

- Passive Parallel Operation: Independent converters share load naturally, though imbalance can occur.

- Active Current Sharing: Uses synchronized feedback loops to evenly distribute power across converters.

- Redundant Power Supplies: Many high-reliability systems use multiple converters for fault tolerance.

How can I minimize noise and interference in a DC-DC converter?

Switching converters can introduce electromagnetic interference (EMI). To mitigate noise:

- Use shielded inductors to prevent EMI leakage.

- Add low-ESR capacitors for filtering high-frequency noise.

- Implement spread-spectrum frequency modulation (SSFM) to distribute noise across a wider bandwidth.

- For ultra-low noise applications, consider using linear regulators after the DC-DC converter.

How should a DC-DC converter be mounted in a design?

The mounting method depends on the application:

- Through-hole components provide better mechanical stability for industrial and automotive use.

- Surface-mount designs (SMDs) are compact but require proper thermal management.

- Encapsulated modules protect against vibration, moisture, and mechanical shock.

How do I protect my DC-DC converter from input power surges?

To protect against voltage spikes:

- Use TVS diodes or metal-oxide varistors (MOVs) to absorb transients.

- Implement LC filtering at the input stage to smooth voltage variations.

- Choose converters with built-in overvoltage and overcurrent protection.

- Use soft-start circuits to limit inrush current at startup.

Ready to power up your next project with a custom DC-DC converter? Contact us today for a consultation!