Types of AC-DC Converters

Switched-Mode Power Supplies (SMPS)

Switched-Mode Power Supplies (SMPS) are the industry standard for high-efficiency AC-DC conversion. By using high-frequency switching technology, they achieve superior energy efficiency while minimizing heat dissipation. These converters are widely used in industrial automation, high-performance electronics, and consumer devices requiring compact, lightweight power solutions.

Advantages of SMPS:

- High Efficiency – Typically above 85%, minimizing power loss.

- Compact & Lightweight – Uses high-frequency components, making it smaller than traditional power supplies.

- Broad Input Voltage Range – Can operate from 110V to 250V AC, adapting to various power sources.

- Scalability – Available in low-power configurations for consumer electronics and high-power options for industrial applications.

Common Applications:

- Computers & Consumer Electronics – Powers desktops, monitors, and gaming consoles.

- Industrial Equipment – Provides stable power for automation and control systems.

- Telecommunications – Used in networking and data transmission equipment.

Isolated AC-DC Converters

Isolated AC-DC converters use transformers or optocouplers to create an electrical separation between the input and output circuits. This isolation improves safety, minimizes electrical noise, and prevents ground loop issues, making them essential for critical applications.

Advantages of Isolated AC-DC Converters:

- Enhanced Safety – Provides isolation from high-voltage mains power.

- Reduces Electromagnetic Interference (EMI) – Essential for sensitive applications.

- Prevents Ground Loops – Ensures stable and noise-free operation.

Common Applications:

- Medical Devices – Used in patient monitoring systems and imaging equipment.

- Aerospace & Defense – Provides isolated power for avionics and military-grade electronics.

- Industrial Automation – Ensures safety in high-voltage environments.

High-Power AC-DC Converters

High-power AC-DC converters are designed for kilowatt-scale power delivery. They incorporate power factor correction (PFC) and advanced thermal management to ensure reliability under continuous high-load operation.

Advantages of High-Power AC-DC Converters:

- Handles High Wattage – Designed for loads exceeding 1kW.

- Includes Power Factor Correction (PFC) – Improves grid efficiency and reduces harmonics.

- Advanced Cooling Systems – Incorporates heat sinks and active cooling for stability.

Common Applications:

- Electric Vehicle Charging – Converts AC mains power to high-voltage DC for fast charging.

- Data Centers – Supplies stable power to server racks and critical IT infrastructure.

- Renewable Energy Systems – Converts AC grid power for solar inverters and battery storage.

Programmable AC-DC Power Supplies

Programmable power supplies allow dynamic adjustment of voltage and current output, making them ideal for R&D, automated testing, and specialized industrial applications.

Advantages of Programmable AC-DC Power Supplies:

- Customizable Voltage & Current Output – Enables precise power control.

- Remote Operation & Automation – Supports integration into automated test setups.

- Wide Voltage Range – Suitable for a variety of applications.

Common Applications:

- Research & Development – Used in lab environments for prototype testing.

- Automated Test Equipment (ATE) – Essential for quality assurance and product validation.

- Battery Testing & Simulation – Simulates different charging and discharging conditions.

Custom vs. Off-the-Shelf AC-DC Converters

When selecting an AC-DC power supply, the choice between custom-designed and off-the-shelf solutions depends on factors like performance, efficiency, cost, and application-specific requirements.

Off-the-Shelf AC-DC Converters

Pre-designed, mass-produced AC-DC converters are widely available and serve general-purpose applications.

Advantages:

- Faster Deployment – Ready-to-use, reducing development time.

- Lower Initial Cost – Economies of scale make them cost-effective.

- Certified for Compliance – Most commercial models come pre-certified for UL, CE, FCC, and IEC standards.

Limitations:

- Limited Customization – Fixed voltage and current ratings may not fit all needs.

- Size Constraints – Standardized form factors may not be ideal for compact or embedded applications.

- Efficiency Trade-offs – May include unnecessary features or lack optimizations for specific use cases.

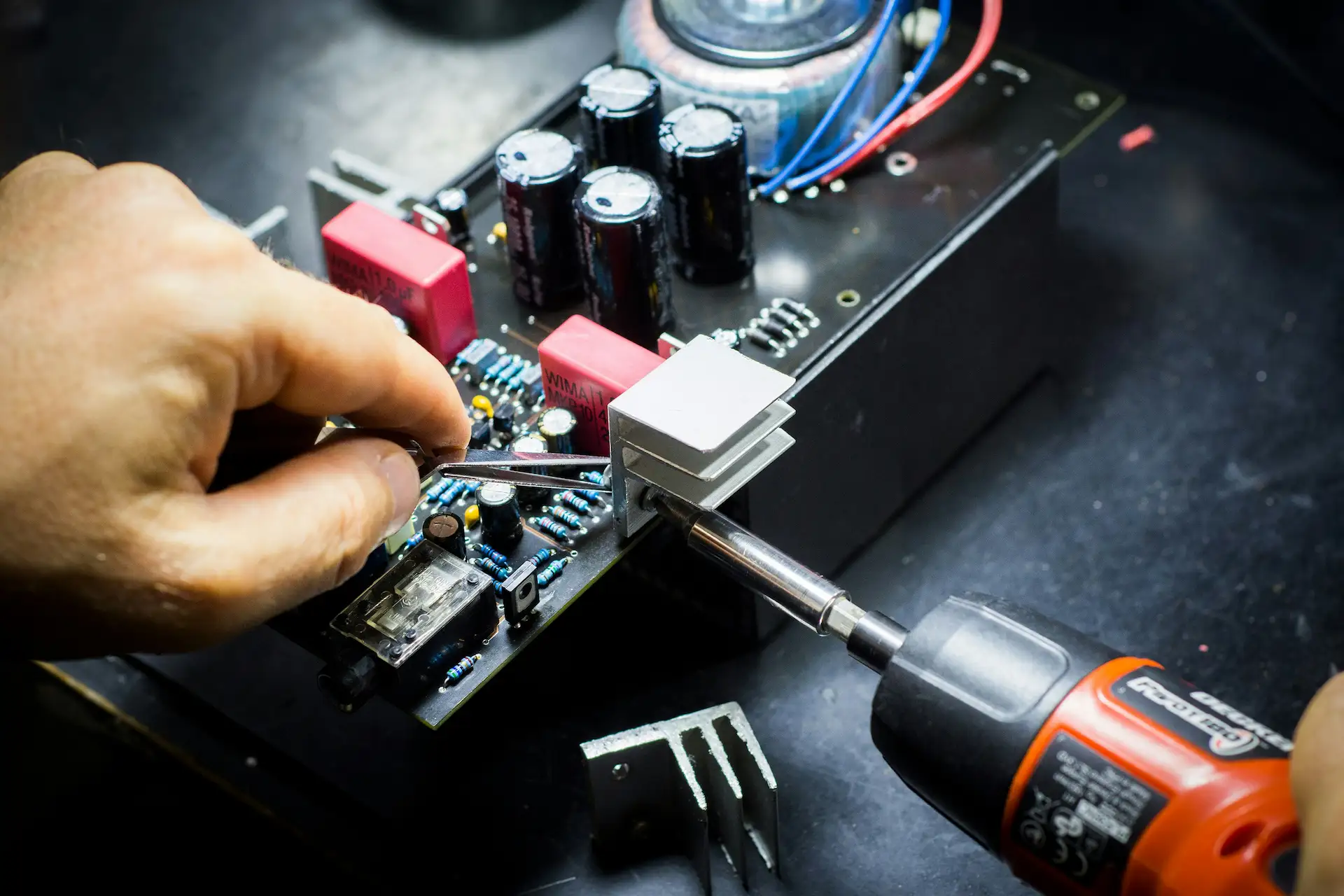

Custom AC-DC Converters

For applications with strict performance, size, or efficiency requirements, a custom-designed AC-DC converter can be the ideal solution.

Advantages:

- Optimized for Your Application – Designed to match your exact power, size, and environmental requirements.

- Higher Efficiency – Tailored components minimize power loss and thermal output.

- Flexible Form Factors – Designed to fit into compact enclosures or integrate directly onto PCBs.

- Advanced Protection Features – Includes specialized safety mechanisms like isolation, redundancy, and smart monitoring.

When to Choose a Custom Solution?

- You require specific voltage or current outputs beyond standard ranges.

- Your application needs high efficiency for energy savings and thermal management.

- Space constraints demand a custom form factor that off-the-shelf units can’t provide.

- You need robust EMI/EMC compliance for industrial or medical applications.

Making the Right Choice

If an off-the-shelf solution meets your needs, it’s the quickest and most cost-effective option. However, if you need better performance, efficiency, or integration, investing in a custom AC-DC converter can significantly enhance your power system’s reliability and long-term cost-effectiveness.

Need a custom AC-DC solution? Get in touch for a free consultation on optimizing your power supply design.

Key Design Considerations for AC-DC Converters

Designing or selecting an AC-DC converter requires careful consideration of several key factors to ensure efficiency, reliability, and compliance with industry standards. Below are the most critical aspects that influence the performance and longevity of AC-DC power supplies.

1. Efficiency & Power Loss

Efficiency is crucial in power supply design, as wasted energy converts to heat, which must be managed to prevent thermal issues.

- Switching vs. Linear Efficiency – SMPS units typically exceed 85-95% efficiency, while linear power supplies operate at lower efficiencies.

- Load Dependency – Efficiency varies based on load percentage; optimizing for typical operating conditions improves performance.

- Thermal Dissipation – High-efficiency designs reduce the need for large heatsinks and active cooling.

2. Voltage & Current Ratings

Ensuring the correct voltage and current ratings is essential for device compatibility and safety.

- Input Voltage Compatibility – Can range from 110V-250V AC for global applications.

- Output Voltage Options – Common outputs include 5V, 12V, 24V, and 48V DC for industrial and consumer electronics.

- Current Capacity – Defined by load requirements; overloading a converter can cause overheating and failure.

3. Regulation & Ripple

A well-regulated power supply ensures stable output voltage under varying loads.

- Tight Voltage Regulation – Keeps voltage within ±1-5% to prevent fluctuations affecting sensitive circuits.

- Low Ripple & Noise – SMPS designs often include LC filters and feedback loops to minimize high-frequency noise.

- Dynamic Load Response – Rapidly adjusts to sudden changes in power demand without significant overshoot or sag.

4. EMC & Noise Suppression

Electromagnetic interference (EMI) can cause malfunctions in nearby electronics and must be controlled.

- Compliance with EMC Standards – CE, FCC, and CISPR compliance is critical for commercial products.

- Shielding & Filtering – Ferrite beads, common-mode chokes, and capacitors help reduce conducted and radiated EMI.

- PCB Layout Considerations – Proper trace routing and grounding techniques minimize noise coupling.

5. Isolation vs. Non-Isolated Designs

Isolation enhances safety and performance by separating the input and output circuits.

- Transformer-Based Isolation – Used in medical, industrial, and high-voltage applications to prevent shock hazards.

- Non-Isolated Designs – More compact and cost-effective but require additional precautions in high-voltage environments.

- Galvanic Isolation Benefits – Prevents ground loops, improves noise immunity, and enhances system reliability.

6. Thermal Management

Effective heat dissipation is necessary to maintain long-term performance and prevent overheating.

- Active vs. Passive Cooling – Fans, heatsinks, and heat spreaders help manage thermal loads.

- PCB Design Considerations – Thick copper traces, thermal vias, and heat-spreading layers improve heat dissipation.

- Temperature Ratings – Industrial-grade power supplies operate in -40°C to 85°C environments.

7. Protection Features

A robust power supply includes safety mechanisms to prevent damage from electrical faults.

- Overvoltage & Undervoltage Protection – Ensures that sensitive components are not exposed to damaging voltage levels.

- Overcurrent & Short Circuit Protection – Prevents excessive current draw, which can overheat and damage components.

- Surge & Transient Suppression – MOVs, TVS diodes, and fuses protect against power surges and lightning strikes.

Benefits of AC-DC Converters

Direct Mains Power Integration

AC-DC converters eliminate the need for external power sources, allowing devices to plug directly into standard 110V-250V AC outlets.

- Ideal for applications requiring uninterrupted power, such as industrial automation, medical devices, and consumer electronics.

- Reduces reliance on battery-based solutions, lowering long-term maintenance costs.

Custom-Tailored Power Solutions

AC-DC converters can be designed to meet specific voltage and current requirements, ensuring optimal performance for various applications.

- Supports a wide range of output voltages, from 5V for embedded electronics to 48V+ for industrial and telecom systems.

- Can include multiple voltage rails in a single unit, reducing the need for multiple converters in complex designs.

All-in-One vs. Modular Power Designs

AC-DC power supplies can be integrated within a device or exist as an external unit, offering flexibility in design.

Integrated Power Supplies

- Embeds the entire power conversion system inside the device, reducing cable clutter and improving efficiency.

- Common in medical devices, industrial controllers, and consumer electronics.

External Power Bricks

- Separates the power conversion unit from the main device, reducing heat buildup and making replacements easier.

- Frequently used for laptops, routers, and high-power audio equipment to ensure safety and flexibility.

High Efficiency & Power Optimization

Modern switched-mode AC-DC converters achieve efficiencies of 85-95%, minimizing energy waste and heat generation.

- Advanced designs feature power factor correction (PFC) to improve energy efficiency.

- Helps businesses and manufacturers meet energy efficiency standards while reducing operational costs.

Scalability for High-Power Applications

AC-DC power supplies scale from low-power (5W-50W) to high-power industrial solutions (1kW+).

- Essential for data centers, EV charging stations, and factory automation, where continuous operation is critical.

- Allows for parallel operation of multiple power supplies to increase overall capacity in mission-critical applications.

Safety & Compliance Benefits

AC-DC converters are designed to meet safety certifications like CE, UL, FCC, and IEC, ensuring regulatory compliance.

- Includes built-in overvoltage, short circuit, and thermal shutdown protection to enhance system safety.

- Isolation designs improve safety by preventing direct exposure to high-voltage AC.

Frequently Asked Questions

What is an AC-DC converter, and how does it work?

An AC-DC converter transforms alternating current (AC) from mains power (110V-250V) into direct current (DC) suitable for powering electronic devices. It typically consists of a rectifier, filter, and voltage regulation stage to ensure stable and reliable DC output.

What are the main types of AC-DC converters?

- Switched-Mode Power Supplies (SMPS) – High-efficiency, lightweight converters used in consumer electronics and industrial applications.

- Isolated AC-DC Converters – Provide electrical separation for safety, commonly used in medical and aerospace systems.

- High-Power AC-DC Converters – Designed for kilowatt-scale applications like EV charging and data centers.

- Programmable AC-DC Power Supplies – Adjustable voltage and current output for R&D and automated testing.

How do I choose the right AC-DC converter for my application?

- Input Voltage Compatibility – Ensure it matches your region's mains voltage (110V or 230V).

- Output Voltage & Current – Select based on the power requirements of your device (e.g., 5V, 12V, 24V).

- Efficiency & Heat Dissipation – Higher efficiency reduces energy waste and minimizes cooling requirements.

- Isolation Requirements – Opt for an isolated converter if safety and noise reduction are critical.

Why are switched-mode power supplies (SMPS) preferred over linear power supplies?

SMPS units are significantly more efficient (85-95%) compared to linear power supplies, which can waste a large portion of energy as heat. Additionally, SMPS are compact and lightweight, making them ideal for modern electronics.

What is Power Factor Correction (PFC), and do I need it?

PFC improves the efficiency of power supplies by reducing harmonic distortion and ensuring better power utilization. It is often required for high-power applications like industrial automation and data centers to meet regulatory standards.

Can an AC-DC converter handle multiple output voltages?

Yes, some converters feature multiple voltage rails, allowing them to supply different voltage levels (e.g., 5V, 12V, 24V) from a single AC input. This is useful in complex electronic systems.

What is the difference between an integrated power supply and an external power brick?

- Integrated Power Supplies – Built directly into the device, reducing external cabling and improving efficiency.

- External Power Bricks – Separate from the main device, allowing for easier replacements and better heat management.

Are AC-DC converters safe for high-power applications?

Yes, high-power AC-DC converters include safety features like overvoltage, overcurrent, and thermal protection to prevent damage and ensure reliable operation in demanding environments.

How do I reduce electromagnetic interference (EMI) in my power supply?

- Use shielding and filtering components like ferrite beads and common-mode chokes.

- Follow proper PCB layout techniques to reduce noise coupling.

- Choose isolated converters to prevent ground loops and interference.

Can I use an AC-DC converter in renewable energy applications?

Yes, AC-DC converters are commonly used in solar energy systems, wind turbines, and battery storage solutions to ensure stable DC output for inverters and battery management.

What certifications should I look for when selecting an AC-DC converter?

- CE (Europe) – Ensures compliance with European safety and EMI standards.

- UL (USA) – Certification for electrical safety in North America.

- FCC – Regulates EMI emissions in electronic devices.

- IEC 62368-1 – Safety standard for audio/video and IT equipment power supplies.

How long do AC-DC power supplies typically last?

The lifespan of an AC-DC converter depends on design quality, operating conditions, and cooling mechanisms. High-quality units can last 10+ years, especially when designed with proper thermal management.

Ready to power up your next project with a custom DC-DC converter? Contact us today for a consultation!